There is No Planet B

Over 7.3 million hectares of forest are cut down annually for paper production. That’s 20 football fields a minute. By doing this, we are erasing our #1 oxygen source! We believe that trees should stay in the forest, humans should breathe the oxygen, and paper should be made from the fallen leaves. So, we created Releaf – the world’s first paper sustainably made from leaves.

Businesses, consumers, and the planet are looking for alternatives to plastic and paper packaging. Releaf offers the perfect solution.

It is an opportunity for a customer to use environmentally-friendly packaging.

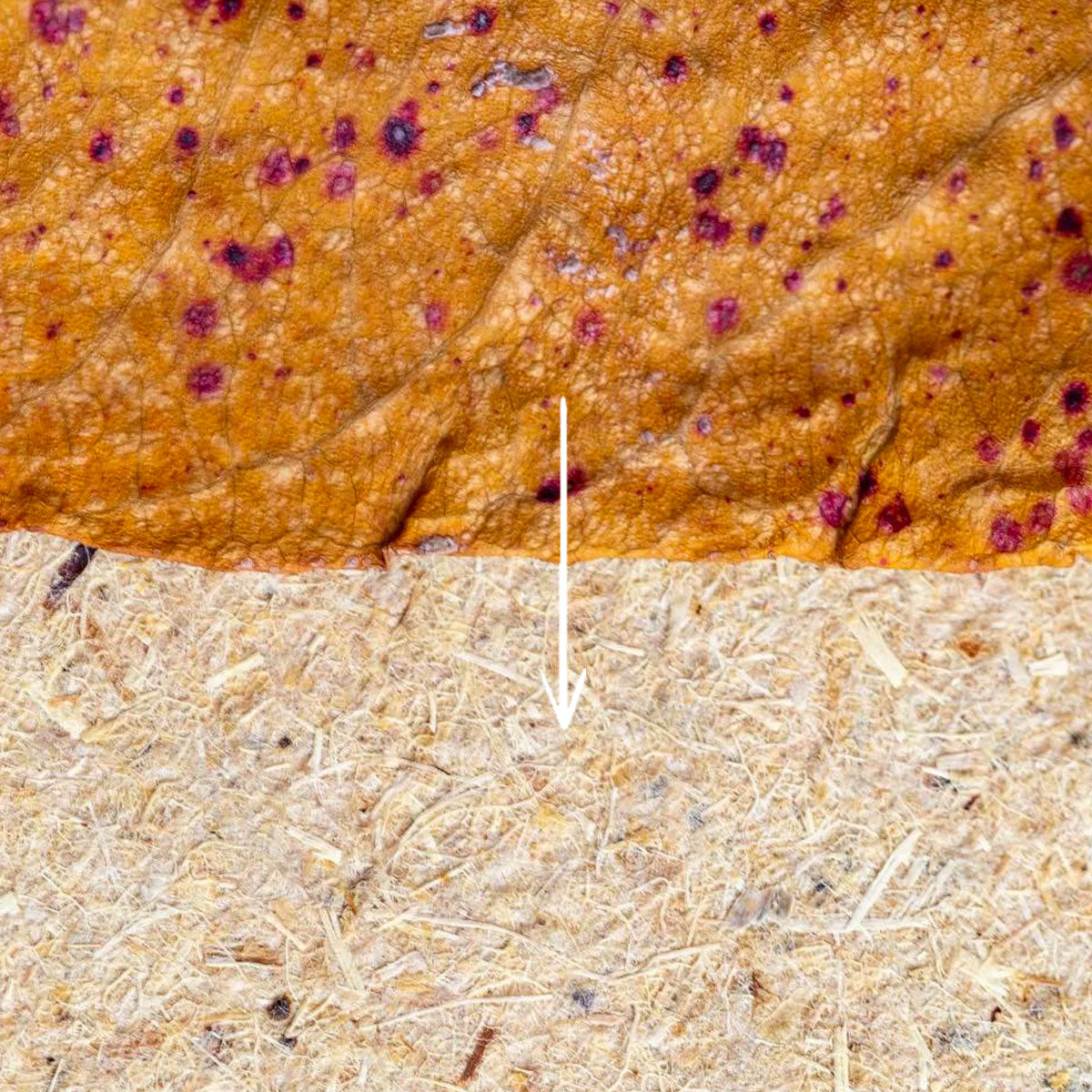

This energy efficient technology turns fallen leaves into paper

One of the best and innovative startups from Ukraine awarded by Google

Unique Technology for Your Unique Packaging

Releaf technology has been in the works since 2017. It provides a revolutionary way to produce paper from renewable, raw materials without the use of harmful chemicals! By purchasing your packaging through Releaf you are contributing to a 78% reduction in Co2 emissions. We are committed to only using leaves and recycled fiber to create the highest quality ‘paper’ that’s just as good (if not better) than the paper we have all grown to love.

Our Global Mission

Together, we can change the approach to packaging and meet demand without compromising our planet. Through Releaf we aim to change the packaging industry forever by providing a way for businesses to be sustainable. In collaboration with global brands, we are spreading the idea of a sustainable alternative to paper without destroying ancient forests.

By using fallen leaves and recycled fiber we can create a new paper that doesn’t risk our lungs, the homes of animals, or the climate.

Help Your Brand Go Green !

More customers than ever value eco-friendly brands. They are looking for companies that are concerned with helping our planet and actually take the steps towards making positive changes. With 100% leaf-based packaging that is reusable and recyclable, consumers will know that you are doing your part to combat the climate crisis.

We are proud to partner with brands across the globe